Why Hydro test required?

After certain service life of pressure parts, piping, vessel or equipment its structure weakens. Weak parts may be initiate leakage or blast of equipment.

When Hydro test takes place higher pressure is taken (Approximately 1.5 times of Operating Pressure) and hold for certain time.

If pressure drop is Zero then Certifier approve it for continue usage.

What Blog Contains...

Blog Contains requirement of hydro testing, Pre-Requirements, Procedure.

[ads id="ads1"]

Pre Requirements

- Equipment, Piping, Joints, Accessories, are as per approved drawing.

- Foundation, Support Structure for equipment should be Installed and adequate condition.

- Visual Inspection of Equipment and/or Piping should be done. If problematic found mark or Paint it for examination.

- Prepare Pre examination report - Final Visual report, NDT - Non Destructive test, PWHT - Post weld heat treatment, PMI - Positive material Identification, Clearence Certificate form Service Department - Lockout and Isolation from Mechanical, Electrical, Instrument, Safety, Civil, IT.

- Pressure Gauges, Pressure Transmitter Calibration should be done.

Hydro Test

Hydro Test Set

Equipment and it's Accessories required for hydro test required is containing

- Filling Pump & Pressurizing pump

- Filling & Pressurizing hose with Valves, NRV- Non Reutrn Valve, PRV- Pressure Reducing Valve.

- Two Pressure Gauges Which are Calibrated before Work with valid certificate.

- Clean Water (DM Water Preferred)

- Hand tools set.

Hydro Test Preparation

Equipment and/or Piping should be prepared for Hydro test. Preparation should be done as following

- Equipment and/or Piping should be vented at highest location so no gas left in Equipment and/or Piping and Drain at lowest Point so Proper drain should be done.

- Equipment and/or Piping and it's joints should be rust, Oil, Grease free. If there is any debrits clean it properly.

- Clean Equipment and/or Piping with Card Board Blasting, Water flushing.

- All Joints Should be Tight. Change Gasket and Nut Bolt if not in Good Condition.

- If any void exists in system like absence of control valve or Instruments should be filled with temporary spools.

- All welds, Joints, Flanges, Screwed Joints left from Hydro Testing. Equipment and/or Piping which are open to atmosphere should not be included for Hydro testing.

Hydro Test Critical check points

- Hydro testing must be done on approved drawings by authorize & Qualified person

- Measure Equipment and/or Piping temperature. It should not be less than 20℃.

- All Pressure Gauges[ Minimum 2 nos in pressuring device and 1 separate with equipment] must be in line and in required range with calibration certificate.

- Clearance from all service department must be obtained and renewed periodically or after break work.

- Pressure pump and accessories must be in detachable after taking pressure.

- One person will be allocated for pressure pump operation. Isolate pump after use.

[ads id="ads1"]

Hydro Test Prcedure

- Fill Clean Water/ DM Water in Equipment and/or Piping with complete removal of air. Complete air removal will be done when all vents are open and overflowed once.

- Close all Entrance and valves, Tight all flanges and Joints.

- For Pressure control, Valves should be available.

- Check clearance form included with area owner, After clearance start taking pressure.

- Pressure will be taken in steps. After reaching pressure check all joints with foaming solution.

- Note pressure and hold for certain period [Holding period will be according to Testing person]

Hydro Test Certification

- After no pressure drop in system over a certain time period release pressure slowly

- Drain water with all vents are open.

- Remove all blind and Isolation.

- If any leakage observed maintenance will be carried out and retesting will be initiated.

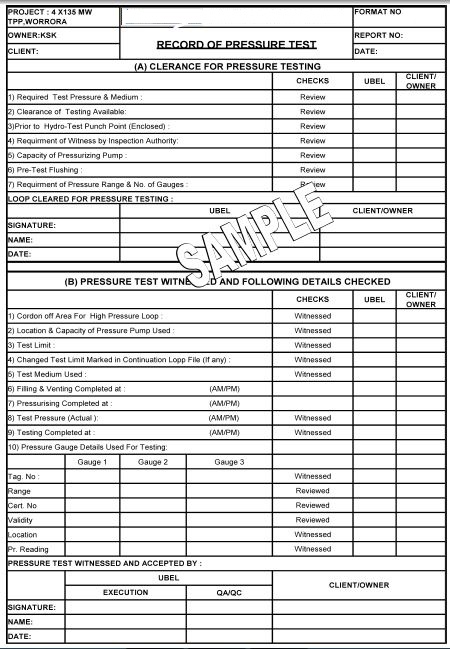

- Records should be maintained during hydro test

Record Format

Thank You So Much for reading Blog

Naitik Patel