Centrifugal pump comparison Horizontal vs Vertical

Industrial centrifugal pumps are two types as per arrangement

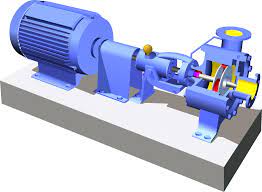

1. Horizontal Centrifugal Pump

2. Vertical Centrifugal Pump

Both have unique usage and applications. We will compare both types in details in each aspect in following

- Defining Parameter

- Foundation area

- Installation requirement

- Maintenance

- Coupling and Alignment

- Radial load [Thrust load]

- Operational range

1. Defining Parameter

Horizontal Centrifugal Pump:

Horizontal pump's shaft is horizontal in Position and laid on ground in operation.

Vertical Centrifugal pump:

Vertical Centrifugal pump shaft oriented vertical. This pumps are generally in Standing or Hanging positions.

[ads id="ads1"]

2. Foundation area required

Horizontal Centrifugal Pump:

High wide foundation area required but less height is required.

Vertical Centrifugal pump:

Less foundation area required but high height is required.

3. Installation requirement

Horizontal Centrifugal Pump:

- Low head room required

- Piping is more complicated.

- Precious adjustment

- Pump alignment is necessory

- Motor mounting space is required

- High head room is required.

- Additional pit barrel is required

Horizontal Centrifugal Pump:

Easy and quick maintenance.

Parts of horizontal pumps are interchangeable.

Parts are less costly and easily available

Vertical Centrifugal pump:

Pump maintenance is time consuming job as well as troublesome job.

Specially skilled required for maintenance of vertical pump.

5. Coupling and Alignment

Horizontal Centrifugal Pump:

After motor or pump maintenance alignment is required. If alignment is disturbed then power consumption will be raised.

In Each preventive maintenance pump coupling and alignment checking is consume time.

Vertical Centrifugal pump:

Vertical pump came with direct drive, rabbet fit, avoids misalignment

[ads id="ads1"]

6. Radial load [Thrust load]

Horizontal Centrifugal Pump:

There are two things available 1. Rolling Element 2. Hydro dynamic which helps to manage axial and radial load.

Bearing house is available to reduce and simplify hydraulic force.

Vertical Centrifugal pump:

High load thrust load is difficult to manage.

Radial and axial bearing pump option is available but costs higher.

Shaft wobbling or improper lubrication results in high vibration and noise.

7. Operational range

Horizontal Centrifugal Pump:

No limit. Pumps are available up to certain thousand m3 flow.

NPSH with sufficient margin is necessory.

Not good for negative ground

Vertical Centrifugal pump:

Vertical pump with high capacity is challenging to install, repair and maintenance.

Vertical pumps are improves NPSH