Centrifugal Pump Interview Questions contains following questions which probably asked in technical Interview

1. What are the different types of centrifugal pump?

Different types of centrifugal pump are:A. Single stage

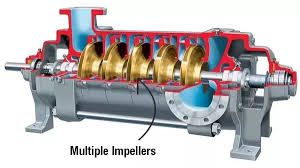

B. Multi-stage

2. What is the basic difference between single stage and multi-stage centrifugal

pump?

The Single stage pump has one impeller and multi-stage pump has two or more impellers in series.

The discharge of one impeller is the suction of the next one and the head developed in all the stages are totaled.

3. How many types of centrifugal pump are available based on the suction and

discharge arrangement?

Based on the suction and discharge arrangement, the type of centrifugal pumps available is: -A. End suction top discharge.

B. Top suction top discharge.

C. Side suction side discharge.

[ads id="ads1"]

4. What is Pump efficiency?

Efficiency of any Equipment means how it can convert one form of energy to another.If one unit of energy is supplied to a machine and its output, in the same units of measure, is one-half unit, its efficiency is 50%.

Efficiency of a centrifugal pump is the ratio of the water (output) power to the shaft (input) power and is illustrated by the equation below:

Ef = PW / PS

Where:

Ef= efficiency

Pw= the water power

Ps= the shaft power

5. What is specific speed, and what is its effect on the pump curve?

Many pump designers reffers specific speed as the most important contributor to centrifugal pump design.It allows the use of existing design and test data to design similar higher and lower flow pumps because the specific speed of a pump is independent of its size.

It is best to think of it as an index number that can predict certain pump characteristics.

Viewed this way, specific speed can be useful when selecting a pump for a particular application and predicting premature failure due to off best efficiency point (BEP) operation.

6. What are individual efficiencies that affect operation?

- Hydraulic efficiency.

The shape and spacing of the impeller vanes have an effect on overall pump efficiency.Although the ideal impeller would have an infinite number of vanes, the real world limits us to five to seven for clear water pumps and even fewer for pumps that handle larger solids.

- Volumetric efficiency.

Whether the volumetric efficiency of a centrifugal pump is a function of the volute or the impeller is debatable (it is probably both), but I will include its effect here.Volumetric efficiency represents the power lost due to flow leakage through the wearing rings, the vane front clearances of semi-open impellers and the balancing holes in the rear shroud.

- Mechanical efficiency

The final piece of the pump efficiency puzzle is that of mechanical losses, although some of these losses are not always included in published efficiency curves.In the case of a frame-mounted pump, these losses are caused by the shaft bearings and the mechanical seal or packing.

For close-coupled pumps, bearing losses are figured into the motor efficiency. Again the rule of thumb follows that of volumetric efficiency, and losses increase as flow and/or specific speed decrease.

- Combined efficiency

When looking at the overall efficiency of a pump in operation, the efficiency of the driver must be included, and in many instances, that driver will be an electric motor.[ads id="ads1"]

7. How do you preserve efficiency?

An important part of the volute is the tongue, or cutwater.Its purpose is to maintain flow into the throat while minimizing recirculation back into the case.

The optimum clearance between the tongue and the impeller periphery is the smallest distance that does not give rise to pressure pulsations during vane tip passing.

A well-designed pump will have a full-size impeller that meets these clearance criteria. When an impeller is trimmed, this distance increases and allows more fluid to recirculate back into the case.

As recirculation increases, hydraulic efficiency decreases.

[ads id="ads1"]

8. How does curve shape affect efficiency?

A typical performance curve is relatively flat at low values of specific speed (Ns) and becomes steeper as Ns increases.Pump efficiency is lowest at low values of Ns (500 and below) and increases as Ns increases.

It reaches its maximum in the mid-to-high 2,000 range and begins to decrease above 3,000.

However, the decrease above 3,000 is much smaller than it is below 1,000.

Steeper curves usually offer a greater range of control when operated under variable speed control against some fixed elevation or pressure head.

These pumps can be problematic when running in parallel or starting against varying system head conditions.

Flatter curves work fine in across-the-line applications as long as the static or pressure head remains relatively constant.

They also work well in closed-loop (and most open-loop) circulation applications when operated under variable speed control.

[ads id="ads1"]

9. When is efficiency important?

The power required by a pump is directly proportional to both the flow and the head that it produces.As flow and/or head increase(s) so does the power required. Conversely, power is inversely proportional to hydraulic efficiency.

For the same flow and head, an increase in efficiency reduces the power requirement.

As the cost per kilowatt hour increases, so will the savings due to increased pump efficiency.

What is the effect of the degree of saturation of dissolved gasses on NPSH?

Compare 100 deg F de-aerated water in a tank with a bladder pressured to 10 psig with a tank without a bladder for the same temperature and pressure, with the pressure provided by, say, a nitrogen bottle causing the water to be saturated with nitrogen.

There is definitely an effect.

The dissolved gas changes the molecular interaction of the liquid in which it is dissolved.

Chemical engineers are familiar with this phenomenon via Henry’s Law, and Oswald coefficient, which relates the V/L (void fraction – the freed-up gas volume to liquid volume ratio) as function of saturation pressure and actual pressure of the mixture.

This is not to be confused with the effect of free gas on pump suction performance, and neither it has anything to do, directly, with cavitation (which is caused by vaporization of liquid and subsequent collapse of vapor bubbles).

The dissolved (not free) gas affects the “ability” of a liquid to become vapor when the pressure drops.

In practice, a good example are cooling water tower double-suction pumps, where the incoming water has been so well aerated when passing through the tower - that a significant amount of air stays dissolved, and reduces the NPSHA.

The NPSH margin (NPSHA-NPSHR) for these pumps is not significant to begin with, and with air affecting the NPSHA, the propensity for these pumps to “get in NPSH trouble” is real.

As an estimate, the reduction of NPSHA for these pumps is about 1-3 feet.

In your case, you should be OK if NPSH margin is good. Also, even if some nitrogen dissolved in water, it will probably stay dissolved and will not come out of the solution at the low pressure inlet areas, because of the time delay – it flows through quickly.

In the cooling tower example, the water stays well dispersed in order to get cooled, i.e. the surface area is extremely enlarged, and air can easily get in.

[ads id="ads1"]

10. Please discuss how pumping water differs from pumping 40% Propylene Glycol. Does the impeller have to change trim to produce the same flow and head with a more viscous solution?

Blankin EquipmentCentrifugal pumps work best on relatively “thin” (i.e. low viscosity)fluids.

The fluid velocities inside the passages of centrifugal pumps are generally much higher then in positive displacement pumps – and higher velocities mean more viscous drag, i.e. lower efficiencies.

Typically, centrifugals are not used above 100 cP or so, although there are exceptions.

Hydraulic Institute Standards have a chart to de-rate the pump flow, head and efficiency (which then allows you to calculate horsepower), as a function of viscosity.

Using this chart, a new (de-rated) H-Q and efficiency curves can be constructed.

The impeller diameter is then determined as usual, using the affinity laws.

11. How Does Pump Suction Limit the Flow?

True, BEP is what a pump designed for, and it would be best if it operated there.However, since the actual operating point is an intersection between the pump curve and a system curve - the pump ends up operating all over its curve, because the system curve changes.

Imagine a discharge valve slowly closing - the system curve (which looks like a parabola) will become steeper - and will intersect the pump curve at lower flow. Same for the opposite - if valve is opening - the system curve becomes "shallower", and will intersect the pump curve at higher flow.

Intersection exactly at BEP is purely coincidental - if the discharge valve is set to make the system curve go right thru the BEP point at the pump curve.

Now, what happens if the valve opens wide enough to get the system curve intersect way past the BEP, at high flow?

Keep in mind that a NPSHr curve also looks like a parabola with flow - it rises sharply at higher flow, past BEP. As it does, the NPSHR gets higher and, eventually, exceeds NPSA (available) - thus cavitation begins.

At low flow, cavitation is not a problem, but "other bad things" happen - the low flow becomes insufficient to "fill the impeller eye", and becomes sporadic, pulsing, etc. - causing pump vibrations, and even mechanical damage.

[ads id="ads1"]

12. Is it true that if centrifugal pump runs in reverse, it will generate zero head?

No. As a rule of thumb, a centrifugal pump running in reverse generates approximately half of its rated head.However, such operation is very inefficient, and motor horsepower would be much higher, as compared with half head operation of a pump running at the correct rotation.

11. What is priming?

Pump casing must be filled with liquid before the pump is started, or the pump will not be able to function.12. What happens to the pressure at the discharge of the pump when the flow increases, or when the discharge valve goes from a fully closed position to fully open?

13. What are the 2 major components of total head?

Static

head and friction head.

14. If you increase the total static head what will happen to the flow?

It

will decrease.

15. If you decrease the discharge static head, what will happen to the flow?

It will increase.

16. Why the Centrifugal Pump is called High Discharge pump?Centrifugal pump is a kinetic device.

17. What is NPSH for centrifugal pump?

NPSH stands for net positive suction head, for any pump to the design & capacity of pump a net pressure head is required which is called net positive suction head.

18. What NPSH is and how to calculate it for a centrifugal pump?

It is calculated as follows

NPSH = Atmospheric pressure + static head - vapor pressure - pressure loss in the suction piping - pressure loss due to the suction strainer.

19. Which pump is more economical than centrifugal pump?

20. Positive displacement pumps are more efficient than centrifugal pump then why Positive displacement pumps are not used in each place?

21. What is use of Euler's equation in pumping?

Pump transferring mechanical energy to liquid flowing and losses.

This energy conversation process is calculated by Euler's equation.

22. Why do we use lubricating oil system in a centrifugal pump? What are the safe guarding systems of a centrifugal pump?

Lubricating oil system is to remove heat from pump bearings

Safe guarding systems of a centrifugal pump

- Pre-warning alarms (Unit Alarms)

- Trip switches

- Safety relief valves

- Seal pot level high low alarms

23. What is the difference between single stage pump and multistage pump?

Single stage pump has only one impeller and multistage pump has two or more impellers

24. What types of bearings are used in a pump?

Sleeve bearings and ball bearings are used in pump.

25. What will happen to bearing, if it is too hot?

If the bearings are too hot they can seize the shaft.

26. Identify main parts of a multistage centrifugal pump and write correct names.

- Upper casing,

- Mechanical seal.

- Bearing housing,

- Suction

- Discharge,

- Lower casing.

27. How do we remove heat from an operating pump?

Excessive heat can be removed from pump by ambient air temperature or by circulating cooling water through water jackets.

28. What is a centrifugal force?

A force, which tends to move an object away from the center of rotation, is called centrifugal force.

29. How a pump driver is connected to pump?

Pump driver is connected to a pump by coupling.

30. What is the function of bearing?

Pump bearings control the side to side movement or radial movement of the Shaft. It also controls the forward and backward movement or thrust of the Shaft.

31. What is the largest part of a centrifugal pump?

Pump casing is the largest part of a centrifugal pump.

32. Which part of a centrifugal pump prevents leakage?

Pump packing is used to prevent leakage from a pump.

33. Label the parts of the closed lubricating system.

Sight glass

Pump

Lube oil cooler

Temp. control valve TCV

Filter

PCV

Reservoir.

34. Where do we use reciprocating pumps in our process system?

Reciprocating pumps are commonly used in Chemical injection where we require high pressure pumping.

35. What should be the position of suction and discharge valves while starting a reciprocating pump?

Suction and discharge valves must be in full opened position and remove air / gas completely from the pump before starting a reciprocating pump.

36. Which part of the reciprocating pump actually moves liquid?

Piston and cylinder helps to move liquid in a reciprocating pump.

37. Reciprocating pumps can not increase the pumping capacity and it can pump only fixed quantity. Why?

Cylinders and pistons are designed to pump fixed quantity. So

Reciprocating pumps can not increase amount of flow.

38. What is a pump cavitation?

When there is no enough (low) suction head pressure, liquid, which is in the eye of the impeller, will move faster causing high temperature to produce vapor.

This vapor lock will produce knocking sound to escape. This will cause pressure surging and loose the efficiency .It can damage the pump. This is called cavitation.

39. How Cavitation can be eliminated in a Pump?

Cavitation means bubbles are forming in the liquid.

· To avoid Cavitation, we have to increase the Pump size to One or Two Inch;

· To increase the pressure of the Suction Head, or

· Decrease the Pump Speed.

40. Why the centrifugal pump is called high discharge pump?

Centrifugal pump is a kinetic device. The centrifugal pump uses the centrifugal force to push out the fluid. So the liquid entering the pump receives kinetic energy from the rotating impeller. The centrifugal action of the impeller accelerates the liquid to a high velocity, transferring mechanical (rotational) energy to the liquid. So it discharges the liquid in high rate. It is given in the following formulae:

Centrifugal force F= (M*V2)/R.

Where, M-Mass

V-Velocity

R-Radius

The formation of cavities (or bubbles) is induced by flow separation, or non-uniform flow velocities, inside a pump casing.

In centrifugal pumps the eye of the pump impeller is smaller than the flow area of pipe. This decrease in flow area of pump results in increase in flow rate.

So pressure drop happened between pump suction and the vanes of the impeller. Here air bubbles or cavities are formed because of liquid vapour due to increase in temperature in impeller.

This air bubbles are transmitted to pump which forms cavitation.

42. What does a pump develops? Flow or Pressure

A pump does not create pressure, it only creates flow. Pressure is a measurement of the resistance to flow.

43. Where Multi-stage pump used

Pressure washing of Aircraft, Trains, Boats and Road vehicles as well as Spray washing of industrial parts and Electronic components.

44. How to apply NPSH in Centrifugal pump in real operation?

1. Before installation / design stage:

Calculate NPSHa for your system (tank pressure, liquid level, suction line design, liquid temp).

Compare with pump vendor’s NPSHr curve at your expected flow rate.

Ensure NPSHa ≥ NPSHr + safety margin.

2. During commissioning:

Check actual suction pressure using a gauge near the pump suction.

Confirm liquid temperature (to get vapor pressure).

Cross-check whether suction pressure + static head – losses still ≥ NPSHr.

3. During operation:

Monitor suction pressure: a drop may reduce NPSHa.

Monitor noise/vibration: Cavitation sounds like “marbles/gravel” in the pump → a sign NPSHa < NPSHr.

Keep suction line free of restrictions: clean strainers, avoid partially closed valves.

Avoid high liquid temperature rises: as vapor pressure increases, NPSHa decreases.

4. If cavitation appears in operation:

Raise suction level (increase static head).

Reduce pump speed/flow to lower NPSHr.

Reduce suction pipe losses (shorter/straighter line, bigger pipe, fewer fittings).

Lower fluid temperature (reduces vapor pressure).

Consider pump with lower NPSHr design (e.g., double-suction impeller, inducer).

4. Quick field example

Pump suction from open tank, water at 30 °C (vapor pressure ≈ 0.43 m head).

Tank water level = 5 m above pump centerline.

Suction pipe losses = 1 m.

Atmospheric head = 10.3 m.

Always check NPSHa against vendor NPSHr at your duty point and keep an operating margin. During operations, monitor suction pressure, temperature, and pump health to ensure cavitation doesn’t occur.

45. What is NPSHa (Available) and NPSHr (Required)?

NPSHa (Available): How much pressure head (above vapor pressure) is actually available at the pump suction in your system. Calculated from suction conditions.

NPSHr (Required): The minimum suction head the pump needs to avoid cavitation, provided by the pump manufacturer curve (tested at specific conditions).

Safe operation rule:

NPSHa must always be greater than NPSHr (ideally by 0.5–1 m margin, or 10–20%).

46. What is Formula for NPSHa?

Formula for NPSHa

For a pump drawing liquid from a tank:

Where:

Patm = atmospheric pressure head

Psurface = pressure on liquid surface (if

pressurized tank; =O if open)

hstatic = static head (liquid level above pump

suction; negative if suction lift)

• hf = friction & losses in suction piping

Pvapor = vapor pressure head at operating

temperature

47. When is a diffuser ring casing used in a centrifugal pump?

A diffuser ring casing is used in centrifugal pumps when high efficiency and smooth energy conversion are required.

It is preferred in pumps designed for medium to high head applications where velocity energy needs to be effectively converted into pressure energy.

Used when stable flow with minimal turbulence and pressure loss is desired.

Ideal for multistage centrifugal pumps and process or industrial pumps handling large volumes with high efficiency.

Commonly used in boiler feed pumps, water supply systems, and chemical process plants where precise pressure control is important.

It is chosen over volute casing when uniform pressure distribution around the impeller is required to reduce radial loads and improve pump life.

Q: What is the effect on flow rate of a centrifugal pump if motor efficiency is reduced by 50%?

Reducing motor efficiency by 50% mainly reduces the power and head output, while the flow rate remains nearly constant if speed is unchanged — but overall pump performance and reliability decline sharply.Motor efficiency affects the power input to the pump, not the speed directly, as long as the motor speed remains the same.

If efficiency drops by 50%, the motor delivers less power to the pump shaft for the same electrical input.

Centrifugal pump performance depends mainly on speed (N) — flow (Q) ∝ N, head (H) ∝ N², and power (P) ∝ N³.

If the speed remains constant, the flow rate will not change significantly, but the pump may not achieve its full head or discharge pressure due to power loss.

In practice, flow may reduce slightly (around 5–10%) because the pump cannot maintain the same performance under load.

Prolonged operation at low efficiency can lead to overheating, vibration, and reduced pump life.

Q. What are the steps for commissioning a centrifugal pump?

Commissioning involves inspection, priming, electrical checks, controlled start-up, performance testing, and final handover to ensure safe and efficient pump operation.

1. Pre-commissioning checks:

Verify pump installation, alignment, and foundation.

Ensure piping, valves, and supports are properly fitted and tightened.

Check oil level in bearings and proper lubrication.

Inspect mechanical seal or gland packing for correct installation.

2. System preparation:

Clean suction and discharge lines; remove debris.

Ensure suction valve is open and discharge valve is partially closed.

Fill the pump casing with liquid to prime the pump (avoid dry running).

3. Electrical and control checks:

Verify motor rotation direction.

Check all instrumentation, protection devices, and interlocks.

4. Trial run:

Start the pump and observe smooth start-up.

Gradually open discharge valve to normal operating position.

Monitor vibration, noise, temperature, and pressure.

5. Performance verification:

Check flow rate, head, and power consumption against design data.

Inspect for leaks and ensure stable operation.

6. Final handover:

Record all parameters and confirm continuous smooth operation.

Handover the pump for regular operation.

Q: What is Suction Head, Discharge Head, and Total Head?

These terms describe the energy levels (pressure or height) in a centrifugal pump system.

1. Suction Head (Hs):

The vertical distance between the pump centerline and the surface of the liquid on the suction side (when liquid is above pump level).

It represents the pressure energy available at the suction.

In case the liquid level is below the pump, it is called Suction Lift.

2. Discharge Head (Hd):

The vertical distance between the pump centerline and the point of discharge of the liquid.

It represents the pressure energy imparted by the pump to lift the fluid to the discharge point.

3. Total Head (Ht):

The sum of Suction Head and Discharge Head, including friction and velocity losses in the system.

Formula:

Total Head (Ht) = Discharge Head – Suction Head + Friction Losses

It indicates the total energy the pump must provide to move the fluid through the system.

Q: What is Centrifugal Force and Centripetal Force?

Centripetal force keeps an object in circular motion by pulling it inward, while centrifugal force appears to push it outward — both representing two sides of the same circular motion phenomenon.

Both Centrifugal and Centripetal forces are related to circular motion of an object.

1. Centripetal Force:

It is the force that pulls an object toward the center of its circular path.

Direction:

Always toward the center of rotation.

Purpose:

Keeps the object moving in a circular path instead of flying outward.

Example:

Tension in a string when a stone is whirled in a circle.

2. Centrifugal Force:

It is the apparent or reactive force that seems to push an object away from the center of rotation.

Direction:

Always away from the center (outward).

It is a fictitious force, observed only in a rotating reference frame.

Example:

Feeling pushed outward when a car takes a sharp turn.

Relationship:

Centripetal force is the real force, while centrifugal force is its reaction or apparent effect experienced in the rotating frame.

Q: What is a Centrifugal Pump Characteristics Curve?

The pump characteristics curve is a vital tool to evaluate and select a centrifugal pump — ensuring optimum efficiency, reliability, and safe operation near the Best Efficiency Point (BEP).

The centrifugal pump characteristics curve shows the relationship between key pump parameters such as flow rate, head, power, efficiency, and NPSH.

It is used to understand pump performance and select the right operating point.

Main Curves on the Graph:

1. Head vs. Flow (H–Q Curve):

Shows how discharge head decreases as flow rate increases.

It defines the basic performance of the pump.

2. Efficiency vs. Flow (η–Q Curve):

Indicates pump efficiency at different flow rates.

The peak point represents the Best Efficiency Point (BEP) — ideal operating condition.

3. Power vs. Flow (P–Q Curve):

Shows input power requirement at different discharge rates.

Helps in motor sizing and energy optimization.

4. NPSH Required vs. Flow (NPSHr–Q Curve):

Represents the minimum suction head needed to avoid cavitation at each flow rate.

Q: Why is a minimum circulation line provided in a centrifugal pump?

A minimum circulation line ensures safe operation, prevents cavitation and overheating, and helps maintain the reliability and longevity of a centrifugal pump during low-flow conditions.

The minimum circulation line (also called minimum flow line or recirculation line) is provided to protect the pump during low-flow or no-flow conditions.

Main Reasons:

1. Prevent Overheating:

When flow is too low, liquid inside the pump recirculates internally, causing frictional heating and temperature rise that can damage seals and bearings.

2. Avoid Cavitation:

Low flow reduces pressure at the impeller eye, which may lead to vapor formation and cavitation, damaging the impeller.

3. Maintain Stable Operation:

Ensures the pump operates above its minimum continuous stable flow, avoiding vibration, noise, and performance instability.

4. Protect Mechanical Components:

Continuous minimum flow prevents excessive radial thrust and mechanical stress on the impeller and shaft.

5. Enhance Pump Life:

Maintains smooth cooling, lubrication, and hydraulic balance, extending pump service life.

Q: What are the types of casing used in pumps and what are the criteria for selecting them?

Types of Pump Casings:

1. Volute Casing:

Spiral-shaped casing where velocity energy is converted to pressure energy.

Commonly used in centrifugal pumps.

Simple design and easy maintenance.

2. Vortex (Whirlpool) Casing:

Has an additional circular chamber between impeller and casing.

Reduces energy losses due to eddies, improving efficiency.

3. Diffuser Casing:

Contains fixed guide vanes around the impeller.

Gradually reduces velocity and increases pressure efficiently.

Used in multistage or high-efficiency pumps.

Criteria for Selecting Casing Type:

Head and Efficiency Requirement:

High head → Diffuser casing

Moderate head → Volute casing

Flow Rate:

High flow → Volute casing preferred

Pump Type:

Single-stage → Volute or vortex

Multistage → Diffuser casing

Maintenance & Cost:

Volute casing is cheaper and easier to maintain.

Application:

Diffuser for precise, high-pressure industrial use; Volute for general purpose.